Concrete Surface Profile and Epoxy Flooring What You Need to Know

Epoxy flooring has gained popularity in recent years due to its durability, aesthetic appeal, and low maintenance requirements. However, before applying epoxy to a concrete surface, proper preparation is essential to ensure a long-lasting and flawless finish. In this blog post, we will explore the necessary prep work for epoxy flooring, including the Concrete Surface Profile (CSP) and the equipment required.

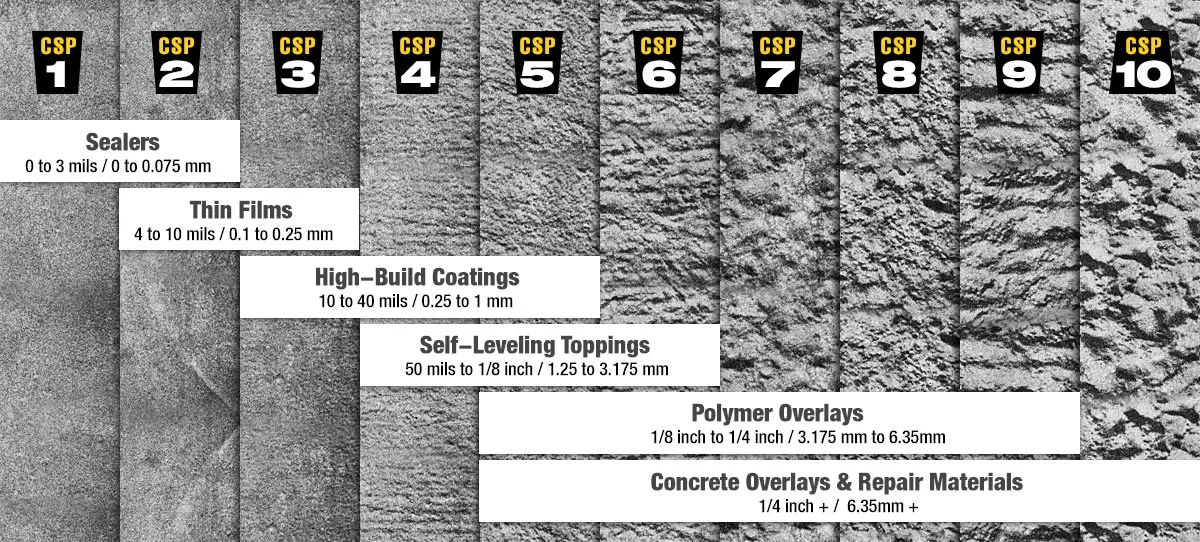

The first step in preparing the concrete surface for epoxy flooring is evaluating the Concrete Surface Profile necessary for the particular coating. The CSP is a measurement that determines the texture and roughness of the concrete surface. It is crucial because the level of CSP will determine the adhesion and bond strength between the epoxy and the concrete. The information here is what you need to know as a consumer so you can make an informed decision.

Classifications of Surface Profile

The Concrete Surface Profile is classified into different levels:

1. CSP-1: This level is the smoothest, achieved by grinding the concrete surface. It is suitable for thin epoxy coatings and decorative applications, but not recommended for high-performance epoxy systems.

2. CSP-2: This level is achieved by Mechanical grinding 16 grit or less, acid etching (although not recommended for many reasons) or shot blasting the concrete surface. It provides a moderate roughness and is suitable for most epoxy coatings.

3. CSP-3: This level is achieved by heavy shot blasting or scarifying the concrete surface. It provides a rough texture and is suitable for high-performance epoxy coatings, such as in industrial and commercial settings.

Equipment Needed to Properly Prepare the Substrate

Once the Concrete Surface Profile has been determined, the next step is to gather the necessary equipment for the prep work. Here are some essential tools and equipment:

1. Floor Grinder: A floor grinder with diamond grinding tooling is used to achieve the desired CSP level. It helps remove any existing coatings, adhesives, or imperfections on the concrete surface.

2. Shot Blaster: A shot blaster uses small steel shots to blast the concrete surface, creating a rough texture suitable for epoxy adhesion. It is an effective method for achieving higher CSP levels.

3. Scarifier: A scarifier is a machine that uses rotating cutters or blades to remove the top layer of the concrete surface. It is useful for heavy-duty surface preparation, especially in cases where the concrete has extensive damage or coatings.

4. Dust Collection System: When performing prep work, it is important to have a dust collection system in place to minimize the release of harmful dust particles. This ensures a clean and safe working environment.

5. Personal Protective Equipment (PPE): Preparing a concrete surface for epoxy flooring involves working with various tools and chemicals. It is crucial to wear appropriate PPE, including safety goggles, gloves, and respiratory protection, to protect yourself from potential hazards.

In addition to the equipment mentioned above, it is also important to have cleaning supplies, such as degreasers and concrete cleaners, to remove any contaminants from the surface before applying epoxy.

Summary

In conclusion, the necessary prep work for epoxy flooring involves evaluating the Concrete Surface Profile (CSP) and using the appropriate equipment to achieve the desired level of roughness. Whether it’s grinding, shot blasting, or scarifying, the goal is to create a clean and properly textured surface for optimal epoxy adhesion. By investing time and effort into the prep work, you can ensure a durable and visually appealing epoxy flooring that will stand the test of time.

Visit our website and see if we are the right company for your epoxy flooring needs!