Epoxy Flooring for Garages

If You're Considering Transforming Your Garage with a Stunning Epoxy Floor This Page Has All the Information You Need.

Give your Garage a Makeover with Durable and Stylish Epoxy Floors. Enhance the Beauty and Functionality of Your Garage with High-Quality Epoxy Flooring. Experience the Benefits of Easy Maintenance, Durability and Aesthetics Appeal with Epoxy Flooring for Your Garage!

Experience exceptional epoxy services with Big Top Concrete Resurfacing in Central Florida. From thorough surface preparation to high-quality materials and professional installation, we are committed to delivering outstanding results. Transform your garage with customized epoxy flooring solutions. Contact us today for a free consultation and let us enhance the beauty and functionality of your space! Keep reading to learn more about epoxy flooring. An educated consumer is a wise consumer.

Frequently Asked Questions

The duration of the epoxy flooring process depends on several factors, including the condition of the substrate and the type of epoxy flooring system being installed. Typically, for a standard two-car garage without any underlying issues, the process takes about two days. We prefer not to rush the process into a one-day timeframe, as our experience has shown that fast drying systems do not sufficiently wet the concrete or absorb into the pores.

Epoxy flooring is known for its durability and longevity. When properly installed and maintained, epoxy flooring can last for many years, even decades. The lifespan of epoxy flooring depends on various factors, including the quality of the materials used, the level of preparation done on the substrate, and the amount of traffic and wear the floor receives.

In normal residential settings with normal foot traffic, epoxy flooring can last anywhere from 10 to 20 years.

Yes, epoxy flooring can be installed outside, but it's important to note that all coatings are not designed to withstand exposure to UV rays and outdoor environments, which can cause the epoxy to fade, discolor, or degrade over time.

However, there are specialized epoxy coatings available that are specifically designed for outdoor use. In particularly a MVB epoxy or Moisture Vapor Barrier epoxy which is our standard go to product.

There are several reasons why you should not install epoxy over tile:

- Adhesion issues: unless the tile is properly prepped all the way down into the grout lines then it's unprepped.

- Uneven surfaces: Tile surfaces are not always perfectly flat and smooth.

- Moisture trapped: If there is any moisture present beneath the tile, it can become trapped beneath the tile and epoxy coating. This can lead to long term damage and failure. As well as mold growth etc.

- Expense: you will spend more money trying to create a level surface and hide the grout lines by filling with additional coats of epoxy. It is more cost effective to have the tile removed.

- Warranty: If there is a failure the very first thing a manufacturer will look at is the substrate. If there is tile present it automatically negates any manufacturer warranty.

No, it's 20x stronger or maybe 50x stronger... Just kidding. But seriously, the marketing that goes into pushing certain products to capture the consumer can be pretty intense and confusing. While each product has its place in the industry, it is important to note that our expertise comes from over twelve years in the business. We prioritize installing resinous products that we have found to be effective, without resorting to fear-mongering or aggressive marketing tactics.

We have perfected our dust capturing process, ensuring that approximately 97% of the dust generated during floor processing is effectively contained. While it is inevitable that some dust may still be present, we go through great lengths to minimize any potential escape of dust particles from our equipment, thereby prioritizing a cleaner, healthier work environment.

Big Top Concrete Resurfacing, LLC has been in business since 2012. We do not inflate our experience or time in the field. You can look up when we created our LLC here:

Do yourself a favor and look up our competitors here:

Absolutely not and let's go over the reasons why:

They can often be misleading and have a number of limitations and conditions that make them difficult to actually utilize.

Look at the fine print that limits the coverage to specific parts or components of the product. Is the coverage prorated meaning that as time goes on, the coverage decreases. So, if a product fails after a certain period of time, the warranty may only cover a small portion of the repair or replacement. What about the exclusions and restrictions?

Ultimately as a consumer you need to know if it sounds too good to be true it is. We are honest and upfront with our clients. On residential epoxy you will get a five-year warranty from a company who has been at it over twelve years. The math just makes sense. If you have a problem call us, we aren't going anywhere.

Concrete Surface Profile and Epoxy Flooring What You Need to Know

By Anthony Commarota |

Concrete prep for coating

By Anthony Commarota |

Surface Prep the Critical Step for Epoxy Flooring for Garages

Epoxy Flooring for garages requires thorough surface preparation it is crucial for a successful installation. It involves meticulous cleaning, repairing any cracks or imperfections, and ensuring proper adhesion of the epoxy to the substrate. The surface must be free of any grease, oil, dirt, or other contaminants that can interfere with the bonding process. This typically involves using a combination of mechanical methods such as grinding or shot blasting to remove any existing coatings or roughen the surface for better adhesion. Any cracks or damaged areas need to be filled and leveled to create a smooth and seamless surface. Proper surface preparation ensures that the epoxy adheres securely to the substrate, minimizing the risk of delamination or premature failure. It is a critical step that sets the foundation for a durable and long-lasting epoxy floor.

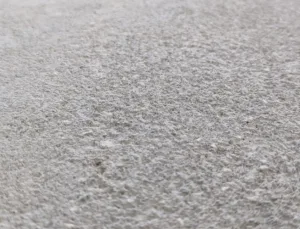

The above image would depict a CSP (concrete surface profile) 4. This is suitable for coatings that require a strong bond such as cementitious overlays or urethane cements. The rough texture of this profile provides a larger surface area for the coating to adhere to. The type of coating that requires this level of prep would be in a commercial environment.

For residential garage floor epoxy our preferred CSP is between 2-3. This also depends on the manufacturer and the characteristics of the epoxy. Understanding these factors is critical for an installer and more the reason you should consult with a coating's specialists for this type of work. Unfortunately, painters and handymen generally will not have the product knowledge and be able to achieve the required CSP.

A Clean Substrate is a Must

You can imagine that prepping concrete for garage floor epoxy can generate a substantial amount of dust. We capture 97% of that dust through large hepa-filter vacuums. These vacuums high a very high CFM (cubic feet per minute of suction) compared to your average shop-vac. They are able to pull the surface dust off the slab much more efficiently. This is a sure way to tell if you hired a professional by the type of vacuum they show up with.

Let's Flake it!

Throwing vinyl chips into epoxy is a popular technique used to create a visually stunning and unique flooring finish. It involves scattering colored vinyl chips or flakes onto a wet epoxy coating, allowing them to become embedded and bonded within the epoxy as it cures.

The process begins by applying a base coat of epoxy onto the prepared floor surface. While the epoxy is still wet, the vinyl chips are broadcasted or scattered evenly across the entire surface. The amount of chips used can vary depending on the desired density and appearance. Once the chips are applied, a clear topcoat of polyaspartic or polyurethane is typically applied over the chips to encapsulate them and provide a smooth and protective finish.

The result is a vibrant, multi-colored floor with a textured appearance. The vinyl chips create a speckled or mottled effect, adding depth and dimension to the floor. This technique not only enhances the visual appeal of the floor but also helps to mask imperfections and provides a more forgiving surface for hiding dirt and stains.

Moreover, the vinyl chips also offer functional benefits. They provide additional traction and slip resistance, making the floor safer, especially in areas prone to moisture or spills. The chips can also help to minimize the visibility of scratches or wear over time, extending the longevity of the floor coating.

Overall, throwing vinyl chips into epoxy creates a beautiful, durable, and low-maintenance flooring option that can be customized to suit various design preferences and enhance the aesthetics of any space.

Mrs. Davidson - "Our garage floor is beautiful ..Anthony did an amazing job...I felt like I needed to pay him more ...Thank you so much"

Mr. and Mrs. Smith - "Anthony, with Big Top, is very knowledgeable and helpful when choosing the colors and flake amount for our epoxy garage floor. His work ethic and workmanship are excellent. He is truly a craftsman. We highly recommend him and his company."

Mr. Politano -"I've contracted Big Top for two flooring jobs in my residence. First they poured my epoxy floor and then recently I requested sanding/re-clear coating/waxing.

Anthony is a great guy, who will work with you to give the best deal and quality possible. He cares about the results and takes pride in his work. He performed an extensive process to do the original epoxy floor install (over a 7 day period) and was very thorough. He is friendly, knowledgeable, and experienced.

This floor has lasted 8 years with only minimal regular maintenance by me through that time (regular Swiffer cleaning and mopping)."

Mr. Gross - "Anthony and his crew did a fantastic job rehabbing my concrete driveway, walkway, and back patio, and staining and sealing it. They repaired the cracks so that you can’t even tell they were there. One crack was really bad and sunken, and they were able to repair if and make it disappear. I was wowed at how well it turned out. My driveway, walkway, and back patio look better than they did when I moved in!"